Services

Engineering

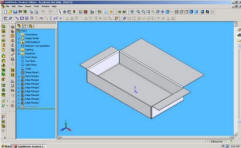

In order to manufacture a sheet metal component, customer supplied information and drawings must be translated into machine code. Many variables must be taken into account to successfully convert a customer drawing into a finished part. Many times, a part can not be economically manufactured as drawn or with customer provided information only. Sheet Metal Service's talented sheet metal engineers and programmers are trained in the use of the latest 2D and 3D CAD technology available which aids in the process. In most cases a design can be optimized for manufacturing through the use of 3D modeling techniques, reducing manufacturing labor and material.

Solid Modeling / CAD

We support our customers designs in SolidWorks, Pro/E and AutoCad.

Rapid Prototypes

Our customers have access to our prototype introduction services

for all first time builds. We not only verify the product to meet

customer needs but also proof the documentation so production can be

supported without delay or interruption. Strict revision control

guidelines are documented. Our design service is versed in

mechanical, thermal and test design practices. We design with

manufacturability, cost, and material availability in mind.

Research and development assistance

Let our application specialists assist you with research and development for your project.

Request Information

Contact

Address

2310 E. Orangethorpe Ave, Anaheim, CA 92806

Telephone

(714) 446-0196

FAX

(714) 446-0119

Electronic Mail

General Information: info@smsfab.com

Sales: sales@smsfab.com

Customer Support: support@smsfab.com

Webmaster: webmaster@smsfab.com